Stretch Film Solutions from Group O

Stretch film, also known as stretch wrap or pallet wrap, comes in various types designed to meet specific packaging and shipping needs. The choice of stretch film type depends on factors like the type of load, the method of application, and the level of protection required. The right stretch film will protect your product and prevent hazards in your warehouse and reduce damage during transportation.

The Group O team is here to help you find the right stretch film for your application!

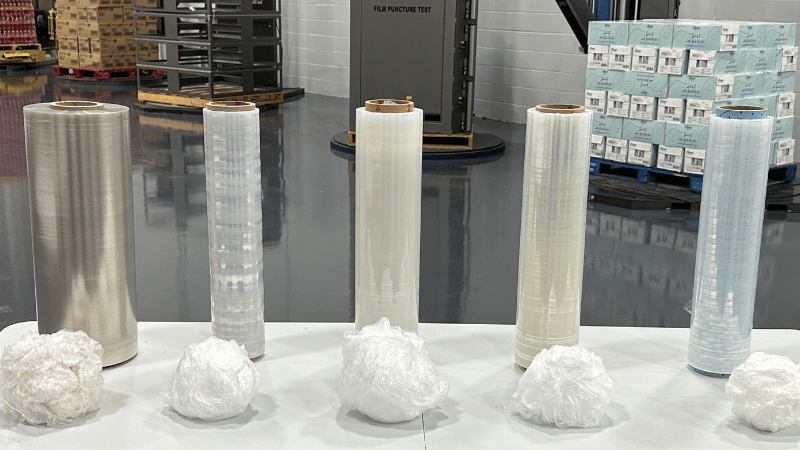

Types of Stretch Film

Let's take a look at available stretch film types, and then find the right solution for your business:

Hand Stretch Film: Hand stretch film is designed to be applied manually. It is commonly used for smaller loads or when a machine wrapper is not available. Hand stretch film typically comes in rolls that are easy to handle.

Machine Stretch Film: Machine stretch film is intended for use with automated stretch wrapping machines. It is available in larger rolls and is designed for high-volume applications. Machine stretch film is applied more consistently and quickly than hand stretch film. Group O even has options for 30% PCR machine-grade stretch film, so make sure to ask our team!

Pre-Stretched Film: Pre-stretched film is designed to reduce the effort required to stretch the film during application. It is pre-stretched in the manufacturing process, making it easier to handle and requiring less force to achieve proper load containment. This type of film can reduce worker fatigue.

Colored Stretch Film: Colored stretch film is used for various purposes, including color-coding different pallets or loads for identification, security, or branding purposes. It is available in various colors and can be used with hand or machine application.

Heavy-Duty Stretch Film: Heavy-duty stretch film is thicker and stronger than standard film, providing additional puncture resistance and load stability. It is suitable for larger and heavier pallets or for securing sharp-edged items.

Other Specialty Stretch Films: UV inhibitor stretch film protects from exposure to sunlight and UV radiation. Anti-Static Stretch Film is designed to dissipate static electricity. Bundling stretch film is narrower and is primarily used for bundling smaller items vs. pallets. Looking for a specialty product? Ask our packaging team!

These are some of the common types of stretch film, each with its own unique features and advantages. Choosing the right type of stretch film depends on your specific packaging and shipping requirements. Ask the Group O team about our packaging optimization process to make sure you’re using the best packaging materials and equipment for your applications.

Gauges

Group O has numerous options of stretch film gauges available. Understanding the applications for these gauges will help guide you to select the right stretch film for your products.

Common stretch film options include:

37 Gauge (9.5 microns): This film is an ultra-high performance film that is used in high-speed applications.

60 Gauge (15 microns): This film is often used for lightweight or less demanding applications. It provides minimal puncture resistance and load containment.

70 Gauge (17.5 microns): Slightly thicker than 60 gauge, 70-gauge stretch film offers slightly better strength and puncture resistance. It is suitable for light to medium-duty applications.

80 Gauge (20 microns): This is a popular choice for general-purpose applications. It provides a good balance between cost and performance and can handle a variety of loads.

90 Gauge (22.5 microns): 90-gauge stretch film is thicker and offers increased puncture resistance and load stability. It is commonly used for medium to heavy-duty pallet wrapping.

100 Gauge (25 microns): Considered heavy-duty, 100-gauge stretch film provides enhanced load containment and resistance to punctures. It is suitable for larger, heavier pallets.

120 Gauge (30 microns) and higher: These are extra heavy-duty stretch films designed for the most demanding applications. They offer maximum load stability and protection against punctures and tears.

Keep in mind that these are general guidelines, and the appropriate gauge of stretch film may vary depending on factors such as the weight and shape of the load, transportation conditions, and storage requirements. Our team will help you find the best gauge for your needs.

Stretch Film Optimization

If you’re looking to improve your packaging processes, meet sustainability goals, or simply ensure you’re using the right packaging products for your business, a SMART AUDIT® is the right next move for you. There are specific stretch film qualities you need to consider.

Stretch Film Audit Areas:

Stretch application - Revolutions - Film weight - Film usage

Wrap patterns - Container force - Load dimensions - Stretch percentage

Get started with our packaging team today!

At Group O, we strive to provide our customers with the best packaging products from stretch film to corrugated boxes as well as everything in between. We also want to provide you with helpful information to help educate you on packaging materials as well as optimization of your packaging processes to guide you on a path to cost reduction. Get started with our packaging articles. Contact our team with any questions or for more information!