TRUST EXPERIENCE.

Group O performs non-destructive and destructive testing on nearly one million devices annually. We work directly with carriers, OEMs, and remanufacturers to customize testing procedures to certify new and current suppliers, as well as any new models or process changes. By fine-tuning standards for remanufactured and new devices, before they hit the market, Group O creates a premium customer experience.

NON-DESTRUCTIVE TESTING

As part of our First Article Inspection, Group O technicians perform non-destructive tests on hundreds of thousands of devices annually. We work with you, your remanufacturers, and new product suppliers to create testing to meet your specifications. We take pride in our ability to adapt to new initiatives quickly so your customers' devices work right out of the box.

Our non-destructive testing protocols include:

- X-ray testing to validate OEM parts

- IP 67/68 testing to confirm water-proofing

- Oleophobic tests to ensure the glass is performing properly

- Radio Frequency (RF) tests confirm network connectivity

- XRF testing uncovers counterfeit components

- Functional performance testing of speakers, microphones, light sensors, power & connectivity, calls & texts, sounds & screens as well as visual inspection checks.

DESTRUCTIVE TESTING

Destructive testing gives you the confidence that the product customers receive will stand up to everyday life.

- Automated and slow-motion captured drop testing discovers structural weaknesses

- Automated tumble testing mimics common end-user experiences

- Submersion testing validates water-proofing

- Impact testing proves the strength of screens

- Tear down inspects workmanship and non-compliance

Group O is an independent testing partner for one of the largest telecommunication & entertainment providers in the world.

SOFTWARE FLASHING & REIMAGING

We manage the entire installation process for custom software on any device. Our experts configure, enable or disable features, and install operating systems and applications specific to your business needs.

Group O also:

- Manages files and apps on employee devices

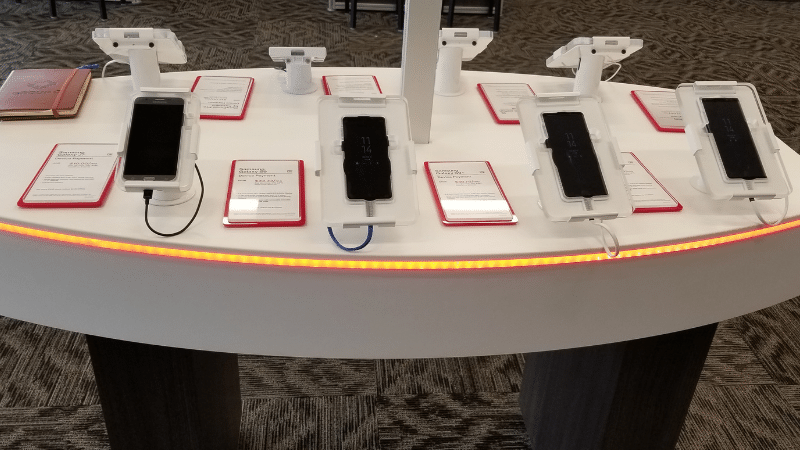

- Manages software on demo units

- Installs specific software applications for customers or employees

- Conducts personal privacy clear

- Detects malware and spyware

Group O installs custom software on all retail devices for Samsung's iconic launches. It is part of the end-to-end supply chain solution Group O provides for each launch.

ENGINEERING EXPERTISE

What makes our device life cycle management services the best in the industry? Our people. Group O’s product reliability and process engineers determine the most effective ways to test a product or service to increase productivity, quality, and efficiency.

INDUSTRIAL ENGINEERS

The team of industrial engineers increases efficiencies across all of our efforts. When creating processes for devices, this team tests cycle times to optimize line balancing. They can find bottlenecks quickly and manage workload to get the process moving at peak efficiency. By implementing 5S techniques, our industrial engineers analyze workspaces to cut down on movements by our testing professionals – the leaner the process the less time it takes to test a product. It's not just efficiency in the workspace, but also throughout the facility. Using AutoCAD, our team designs our spaces down to the most minute details.

RELIABILITY ENGINEERS

Our team of reliability engineers discovers and implements new technologies for our testing labs. It takes a lot of planning and expertise to keep testing services current, as new types of devices enter into the testing process frequently. Reliability engineers focus on work patterns and write detailed instructions for each test for each device. Our instructions are so thorough that clients use our documents to train their other operations, including OEMs providing remanufactured and new devices for testing.

Our engineering professionals can create systems and efficiencies because they’ve been doing it for years – and can do it for you and your business.

DEVICE LIFE CYCLE MANAGEMENT

Group O is one of the only companies in the industry that provides device quality testing and a full supply chain solution.

RETAIL FULFILLMENT AND LOGISTICS

Our supply chain solutions for retail include order fulfillment, inventory management, distribution, and more.