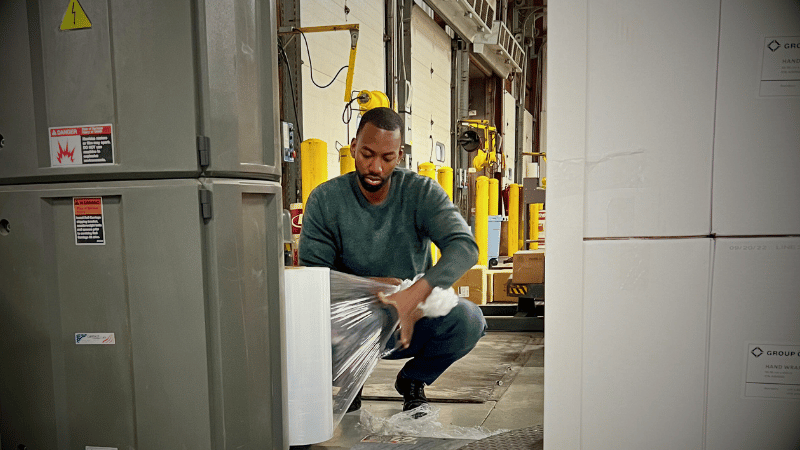

Optimize your packaging process

For your packaging optimization needs, talk to the experts at Group O. Utilizing our SMART Audit® system, we can increase cost savings while identifying key packaging and material inefficiencies in your current packaging process. We’ll work with you to make sure you get the most out of your packaging materials, while providing key insights into both your stretch film usage and equipment efficiency.

In addition to providing packaging materials and equipment, Group O becomes a true partner to your supply chain by evaluating your packaging material and equipment regularly. Our practices for package optimization ensure the successful packaging and shipment of a product, resulting in significant savings for your supply chain. Our team is dedicated to you — our customer — and we ensure your packaging operations are fully optimized, efficient, and cost-effective.

Our SMART Audit® program is a critical factor in helping your business achieve packaging optimization and success, as we seek new ways to optimize your stretch film usage and other packaging needs. We’ll identify potential areas of improvement and provide innovative and practical solutions. Our team is flexible, dedicated, and technology-driven to lead you and your supply chain into a successful future. We listen to your concerns and analyze your packaging process each step of the way — from packaging design to transport packaging. We will collaborate with you to come up with a viable solution for packaging and shipping a product, eliminating potential product damage and reducing shipping costs.

Together we can come up with a solution to help your business succeed.

What is a SMART Audit®?

To understand current stretch wrapping operations, we come to your facility to get a baseline of film use, machine settings, and process efficiencies. We don't just focus on the technical aspect, we also talk to equipment operators to get a full understanding of the logistics.

Stretch Film Audit Areas:

- Stretch application

- Revolutions

- Film weight

- Film usage

- Wrap patterns

- Containment force

- Load dimensions

- On pallet pre-stretch percentage

Equipment Audit Areas:

- Common wear and tear

- Structural and functional parts

- Recommendations upgrades, retrofits, and parts

SMART Audit Process

- Gather stretch film and equipment data

- Perform a stretch application audit on each line in your facility

- Complete an analysis and develop recommendations

- Calibrate your equipment, make operating protocol changes, recommend material changes and training

- Manage periodic auditing of each application for optimized performance results

SMART Audit Benefits:

- Reduce unit load and transportation costs

- Minimize load failures or product damages

- Leverage spend by standardizing packaging materials across operations

- Minimize downtime and identifies machine maintenance needs

- Increase uptime by reducing unscheduled service

- Usage and cost reduction opportunities

Download our SMART Audit Infographic

Packaging Equipment

We partner with major equipment manufacturers to provide new and used packaging equipment.

Packaging Materials

We can provide you with the packaging supplies and materials you need to optimize your operations.

Parts and Service

Order parts for self-service or rely on our expert team for packaging equipment maintenance.

Welcome to Group O, your gateway to a world of packaging excellence! Explore our cutting-edge SMART AUDIT® process and read our collection of articles covering everything from packaging solutions to equipment and optimization strategies, all aimed at elevating your packaging processes to new heights.

LET'S GET STARTED!

Are you ready to take the next step toward packaging optimization for your business? Together we can create packaging solutions that actually work and are customized to you and your unique business needs. To get started, click the contact us now button below, fill out the let’s get started form, or give us a call at 800.752.0730.